Working at the intersection of craft, design and excellence, Modesti has spent the last twenty years in India building a business employing over 650 people in three factories across Delhi and Bombay, serving five luxury clients. He speaks to us about the real challenges within the craft industry, where his company is responsible and the additional responsibilities they are taking on to ensure the future of the “Made in India” label. Edited excerpts:

You’ve been in India twenty years. What brought you here?

I came as a young graduate of IFM (Institut Francais de la Mode), finishing an MBA in Paris. I proposed a study to the faculty on the opening of the Indian market to luxury brands. They all looked at me as if I were mad but I had a strong intuition and the study ended up helping Lacoste to enter the market. While researching, I was amazed at the exceptional and unique craft in India. I didn’t come with a plan in ‘93 – I wanted to see what could be done. I trained as a fashion designer and had just finished working with Azzedine Alaïa for five years before coming here. I had nothing to do with embroidery and craft in India; it was a happy mistake. The first few years were about R&D; experimenting, developing samples and understanding how the communities worked. That’s about the time Stella McCartney arrived at Chloé and asked me to start doing their embroidery. Working with Azzedine was important because that is how I came to meet many people who are clients and friends, including our relationship with Hermès. Today, we work with a few clients, including Hermès, Isabel Marant and Bibhu Mohapatra. For instance, all of the Hermès embroidery is done by us here. We do embroidery and silk garments in Bombay and leather accessories and garments in Delhi. The idea is to become completely vertically integrated, manufacturing finished products out of our factories and only focusing on the excellency of craft – there is no compromise on quality.

It may surprise readers to know your clients produce in India, including Hermès. What is the value of the ‘Made in India’ Label to your brands?

We are extremely proud of it. I make it a point only to work with people who are proud to be creating in the country. All our products must carry the ‘Made in India’ label. In fact, Hermès has created beautiful ‘Made in India’ labels for their products. Every designer I work with has come to India, I came with Azzedine in ’96, Stella came in ’99 and Phoebe in ’00. I make it a point for the Hermès team to come twice a year, minimum. They must sit on the floor with the karigars and to understand how it works.

I don’t believe in creation that is purely transactional. If you work with me, you must come here, sit on the floor, look at the technique and we then create together. This has given the best results. Firstly, it’s respect for the karigars, because only then you realize how exceptional they are. Secondly, what we can achieve at the level of creation is nothing compared to sending samples back and forth.

Are the perceptions of the ‘Made in India’ label a problem? It is not a problem at the luxury level anymore. However, the working conditions are still a problem. I went to see units in Nagpada in Bombay, where many luxury labels do their work. When you see the working conditions, you cannot accept it. One of the problems is that the industry here is of traders, but this is changing. We are at the turning point between an old industry and a new one. Previously, a label used to place an order with a buying office, they in turn placed an order with the trader and on and on. In the end, there was never any accountability. Today the buyer wants to know where their piece is being made – they come right to the point of origin.

The other issue is that the common client in India is not proud of the Indian craft. They don’t realize the number of hours and amount of work that go into an exceptional sari – handloom or power loom – they don’t understand the difference. It has to change.

India has a huge economic reservoir in craft that is not being harnessed. But I am starting to see a certain consciousness. Indian designers are extremely conscious about it. Behind all the glitzy fashion, there are those that are truly concerned about the craft. I wish they would do more, because when you go to the facilities where it’s produced, it doesn’t match up. By they are conscious in that they need to pay if they want quality. I wish they would pass the message to the customer – to educate the customer about the cotton, embroidery… why it’s exceptional. And mostly, why it’s so important to sustain Indian craft.

Does pride in Indian craft mean we need to preserve it as it is?

No. We need to change it. It is all about design and craft. I disagree with the craft purists in India who say we cannot change things. Not true. The only thing that will keep craft alive is design. Design will save craft; I am a living example of this success. This is the main problem of the craftsmen, they don’t have the design. You cannot keep repeating the same things, one needs to address the liaison between design and craft. I believe only in that. How do you bring design to them? This is something we are working on. Another issue with regards to providing design inputs is education. There are so many fashion schools in India, but the level of quality in their graduates is unbelievably poor. I receive fifty CV’s each month from students of fashion schools and I’m only able to hire one. But I need fifteen. What is shocking is the amount they pay to go to these schools – it’s a serious problem. Four years ago we initiated an exchange program supported by UNESCO and FIMALAC Foundation, between NID (National Institute of Design) and Ecole Duperre in Paris for a four month exchange, giving the opportunity to students to experience design working conditions in a complete different environment. This year will be our 4th edition and I am proud to see the students evolution. However, at this point, I still have to bring people from France. I feel bad because I should be nurturing young grads from here. It’s not the training, it’s just that they all want to be famous. They feel extremely proud for six months working with luxury labels and after that they think they can do it on their own. You know what happens? Nothing happens. That’s the reality.

They think that by opening up a shop you have a brand identity. They haven’t been educated properly and they think they know. Twenty years later I still don’t know, I still have doubts with what I’m doing at times.

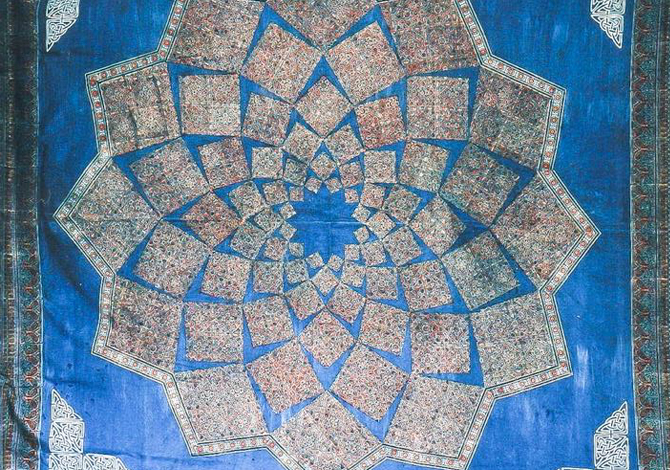

Speaking about design and craft, one of the major criticisms from purists with regards to the Hermès sari collection was that they were not even hand loomed, and exorbitantly price around 5Lac each.

One you’ve seen how the print of Hermès is done then you can truly understand it. The purists will judge based on their history of sari – but if you don’t know how a product is made, how can you comment? In India, you can’t do more than ten colors in a silk screen – it’s a disaster post that. The saris are silk twill printed in thirty two colors. Show me how you can print that – it’s a craft in it’s own right. To be honest, I don’t think think they were expensive enough. When you look at the craft and quality, I would price them closer to 8Lac. They sold out a little bit too fast.

Have you seen a change in the next generation of craftsmen with regards to their willingness to work in the trade?

It will take up to ten years to see that. This is the reason there is an emergency for action to be taken. Craftsmen used to come from the villages and move to the big cities. I don’t believe anymore in bringing the people to the city – it cannot be sustained because of the quality of life and family life of the craftsmen. You are taking people away from their family nucleus. I believe we need to be the ones moving, that’s why we are opening a factory in Agra, it’s being constructed as we speak and will have current employees from Delhi and Bombay moving back to Agra. It will be a trial with fifty people and we will see how sustainable it is.

What is your responsibility to sustaining a craft that is not necessarily valued? For instance, a popular shawl company in Delhi with a shop in Emporio, who also does private label work with international luxury brands, recently said many clients don’t opt for Indigo dyes because there is too much variation in the color and that color fastness is an issue.

This is the international standard – uniformity in production. However for me, one must accept the irregularity of the craft. Denim was popularized in the 1800s with indigo, which then faded and transferred color. Once you’ve seen the process from the leaf to the powder, you realize what the beauty of it is. The deepness of the color is unbelievable. When you have a brand that is sensitive to this, sees the beauty and says, “ok, we are going to do a small collection of 400 pieces knowing the problems. But we are going to educate the client”, it becomes valued for it’s uniqueness.

Given that the future of craft is a complex and large issue, how does one begin to create change?

Today, we don’t have precise numbers to know how many people are employed in the craft industry – we only have rough figures. Everything currently falls under ‘handicraft’. You can be making a cushion for Ikea or the most beautiful embroidery – but it’s all ‘handicraft’. It’s not the same thing.

Everything we’ve spoken of comes down to the same thing: ensuring a vibrant future for the craft industry. These are the problems some of us are trying to address through our work. For instance, with people and organizations like Ritu Sethi (The Craft Revival Trust) and UNESCO, we want to focus on centers for craft excellence. The idea is to take master craftsmen and train them, giving them social recognition as well. Currently, there is no diploma for their work – they learn on the loom, don’t attend school and don’t feel educated. But if you try and do the math on setting up a loom – an ikat for instance – it’s brilliant, most people would not know how to calculate the complex weaving pattern. How do we value that? We need to recognize and value that. At my level I’m trying to create small earthquakes so people can wake up and spend the money. Resources are there. If people realized how much economic power craft has, I am sure they would see it completely differently. It’s a matter of time. India is always a matter of time. I remain optimistic and am clear with my responsibility: to give back to the country what it’s given me.

_________________

Maximiliano Modesti is the Founder and Managing Director of Indian Leather Artisans Pvt Ltd, ARDY 2M design studio Pvt Ltd, and Les Ateliers 2M in Paris.

An interview with meat……. and bones to chew on 🙂 Well done!

it takes a genius to understand geniuses , that’s the feeling I get reading the article , and a true sprit always would face a single problem to retain the trueness of the sprit for enternity

Je suis admirative!

Thanks for sharing this article. Having worked with crafts over a decade i can relate to a lot of things Maximiliano Modesti is saying here. He should get in touch with Judy Frater of Kala Raksha Vidyalaya. They are doing pioneering work with craftspeople and design education.

With all the depth of my heart , I wish Maximiliano for his elegant thought and initiative .

What a lovely story! The tale among this YouTube movie that is posted at this area is really a fine one with having appealing picture feature.

Je viens de voir un reportage sur Arte et j’ai admiré votre créativité,ai été touchée par votre engagement, votre respect et votre grand cœur. Merci et bravo !

Je viens de

Je viens de voir un reportage sur Arte et j’ai admiré votre créativité,ai été touchée par votre engagement, votre respect et votre grand cœur. Merci et bravo !