As seventh generation block printers, the Buddha family has become renowned as specialists in large scale vegetable dyeing, possibly due to a remarkably innovative approach to production. What sets them apart? What drives them to be different?

Two years following the devastating earthquake which shook Kachchh in 2001 the Buddha family from Dhamadka village, like many before, relocated to a newer village, named Ajrakhpur. Seventh generation block printers, their family-run business consists of Khatri Abdul Rehman Buddha and his four sons, Abdul Rajak, Ibrahim, Rashid and Junaid. They have since become renowned as specialists in large scale vegetable dyeing, possibly due to a remarkably innovative approach to production. What sets them apart? What drives them to be different? Neither short on spirit nor enterprise; both father and sons speak about tradition and technology with humility and passion:

Khatri Abdul Rehman Buddha Right now, business is good, margins are comfortable and the youngsters have gotten involved. As long as this continues, we will never give it up. As for the future, awareness of environmental issues like pollution, warming, depletion of water sources is good for our business because people using natural products is on the increase.

What could be considered different about us is that we apply our mind a lot to our product and we try to anticipate what the customer wants. We also study the market and work towards producing quality. We wanted to add practices which would help us save on fuel, water and time. After prolonged trial and error, thinking about how to reduce our inputs, Allah finally gave us the wisdom to adapt machinery to our work which we find very useful now.

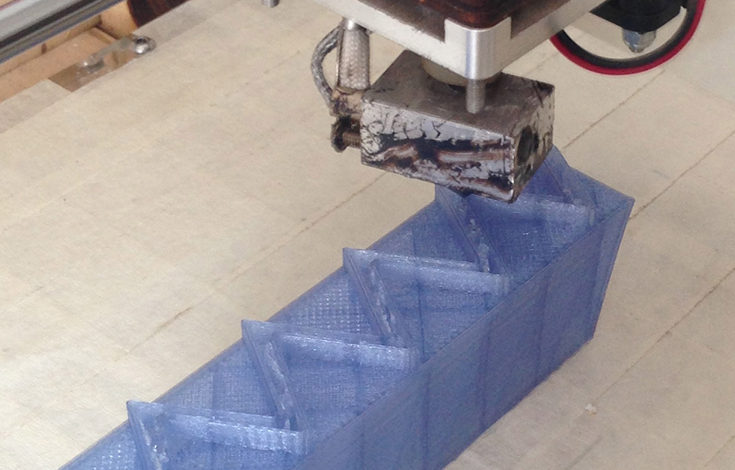

Junaid Our father was the first one to use a drill machine (to make wooden blocks) 12 years ago. A recent idea struck us when we went to Ahmedabad and saw a welding machine; we started making drawings to figure out ways to adapt it. We bought a drill machine and reassembled it, removing tools that we did not need.

Abdul Rehman It was our idea but it is not unique; others can improve on it but until now, no one has. Many of them are doing the same thing. There are about eight or 10 families in our village who use machinery, most of them are among our circle of friends. When they see the advantages, they appreciate it without any resistance. My friends see me as somebody who wants to make changes.

Junaid The need for updated methods arises usually because of market pressure for quicker production, especially with export shipments. We experiment, share and discuss how to make things better and slowly the whole village has started to benefit from these ideas.

Hand blocks, for example, used to take us eight days to make. After we started using machine-made blocks, it takes two. The print goes deeper too, is more evenly distributed and stays longer. We don’t use hand-made blocks very much anymore, the majority of our work uses machine blocks. Not using the technology and science that is available to us would be our fault. Technology has made our time and productivity more efficient, and made life more convenient. We would be stupid not to take advantage of that. Machine block printing has a lesser effect quality wise, the block itself does not.

We treat traditional and fashion motifs as two separate categories, so there is no confusion. Tradition is important as there is a story behind it. If we change the motifs, it is not Ajrakh anymore. I consider ‘fashion’ to be what the market wants and is selling at any given point in time. – Junaid Buddha

Abdul Rehman It’s not as though we have completely automated the process. That would not be good as it would reduce employment – we have only made the process more efficient. Nowadays the same designs are made by big industries as well but many people still like our technique. What should be considered is that our method improves employment opportunities also.

I’m very proud of my sons and what they are trying to achieve. They learn by experience, use their intuition, and their expertise improves day by day. There’s nothing for me to teach them that is a secret anymore. I cannot predict or say now what the Ajrakh block printing technique will be 20 years from now, it depends on the needs of the market. There are uncertainties and new products coming into the market – adapting to change will be necessary.

Comment