ASA is a label borne of designer Shreya Oza’s keen passion for experimenting with fabrics and natural dyes. The recognition of her designs conceals certain realities of running a womenswear brand – at two years and three collections old, she currently retails from her studio and has limited production capabilities, often allowing collections to develop on their own timeline. Continuously exploring new forms of textile, we were taken most by her naivety and curiousity – including the admission of “I’m very young in my practice – whether art or design – and still working out a lot of things” and developing paper fabric from banana pulp and 100% cotton fibres (washable, she swears).

The beginning > While studying interior architecture at CEPT University, Ahmedabad, I had the opportunity to weave on a small handloom as part of a module in woven textiles. The process was calming to me and I wanted to do more; it became one of the reasons I quit CEPT within six months to pursue textile design at NIFT, New Delhi, in 2009.

During my first year at NIFT, I interned with Ramkishor Chhipa, a block printer in Bagru, Rajasthan, and learnt about different kinds of homemade dabu (mud-resist used in hand block printing). The year after, I explored handloom cotton weaving with an ethical fashion brand called Upasana in Auroville, Tamil Nadu. I worked on my graduation project, an extensive study on weaving with merino wool, with Avani, a voluntary organisation in Kumaon contributing to sustainability in the region through handloom textiles.

Above: images | Top: Marble printed textile naturally dyed with harda, pomegranate, indigo and syahi | Below: Multicoloured khadi cotton jacket lined with cotton silk in natural dyes; Naturally dyed and hand block printed garment samples

After college I moved back to my hometown, Ahmedabad, and started to explore working with design experts in different fields – architects, sculptors, print makers. I was open to working in any area of design because that gave me license to observe and think. There seemed to be scope for innovation in fashion that could be imbibed from exposure to other realms of design.

Material explorations > Feeling an inclination toward fabric innovation, I decided to intern with Clay Club in Ahmedabad – a team of entrepreneurial designers working with architecture, ceramics and handmade paper media. I offered to develop paper fabric for them using cotton warp and paper weft. The resulting samples turned out good enough for upholstery so we then used natural dyes in a variety of treatments.

Above: image | Look book Summer Resort 2016 kala cotton khadi dyed suit, image: Manou

Other experiments like combining clay with cotton and burning the mix in a kiln didn’t work. I was aiming for a textile but the cotton burnt away leaving a porous clay lump that looked like laterite stone. I also tried burning jute fibres with cotton pulp to see what happens but nothing substantial came out of it. The one year at Clay Club was all about experimenting with different materials and, though I work independently now, I am somewhat still at that stage.

I have always made materials myself. I can discipline my mind and go deep – searching for, and building themes.

Right now I want to concentrate on and experiment more with paper fabric because it is an amazing concept with a lot of potential. First, I make paper out of banana pulp and then combine that paper with cotton to make fabric. Banana pulp is super strong because of its long fibres so the resulting piece of textile is strong too. I’d like to make this fabric utilitarian but I have to admit, it’s tough to innovate and then make use of that innovation for everyday living. People tend to ask: why do you make paper fabric clothes – are they washable and feasible? Which are valid questions.

Above: images | Top: Cut-out of handknit paper fabric made from cotton paper yarn; Summer Resort 2016 Paper collar jacket | Below: Spring Summer 2015 cork rubber slippers, image: Pynkmenlang Mawnai; Detail of a handknit paper collar

I’ve used paper fabric to make curtain blinds and shirt collars, and a line of bags and shoes are underway. I’ve tumble washed the fabric and it stays fine. You can wash it twice or thrice a month but definitely not as often as regular cotton fabric. I want to make it more refined and then give it to looms to produce in large quantities.

Above: image | Campaign shoot 2015 for debut collection, image: Kassia Karr

ASA by Shreya Oza > I launched my clothing line, ASA, in 2014. It was a result of all the learning I had gained in the two years after NIFT through my year-long internship with Clay Club and also personal textile developments with local weavers around Ahmedabad. I love traditional techniques and the framework behind them, and I enjoy processes, so the idea with ASA has been to create contemporary work which reflects all that.

My first collection, made with handloom fabric and natural dyeing techniques, was quite well received. Nidhi Jacob, fashion editor of Elle, really liked it and ASA got featured on blogs like The Neemly by Kassia Karr, and This is Sheena by Sheena Dabholkar – both blogs that I respect and like to read. I did not apply to Lakme Fashion Week with my first collection because it didn’t occur to me. But in 2015, the Elle team approached me to showcase my Spring Summer 2015 at Amazon India Fashion Week (AIFW).

Above: image | Lakme Fashion Week Summer Resort 2016

I skipped designing a full-fledged Autumn Winter 2016 collection because it was too soon for me to design another 30 looks right after AIFW, and there was also a shortage of resources and funds. I could only make seven pieces. I chose to design for Summer Resort 2016 which was showcased at Lakme Fashion Week.

Before I started out on my own, back in 2013, I worked with Ruchika Sachdeva (of Bodice) to gain some experience but that only lasted a month. Rather than a definite role and working for a set number of hours, I wanted to work at my pace on my own terms and conditions and I wanted to be challenged with multiple responsibilities. Now, having worked independently for two years, I’m trying to achieve balance so that I don’t lose out on opportunities to collaborate.

Above: images | Clockwise from top right: Paper explorations; Spring Summer 2016 banana paper bag; AIFW Spring Summer 2016 handblocked cotton dress with mashru pants & banana paper bag

The struggle > I’ve showcased at LFW once so far, which wasn’t great for me in terms of sales because I do not have the capacity to produce enough. But it’s good to be a part of these shows because they help me stay in touch with what’s going on in the industry and market. In addition, I’ve started looking at galleries to represent my work as a paper textile artist. Tara Chatterjee of Chatterjee & Lal, a Mumbai-based art gallery, likes my work but said that I need to evolve as an artist and be extremely dedicated to my art.

I’m very young in my practice – whether art or design – and still working out a lot of things. As a designer, it’s difficult for any new label to retail – you have to be smart and your business needs to be sustainable which takes time.

In terms of retail channels, in India or internationally, my ideal stockist would be a store keen on promoting new talent that likes to stay on top of new tastes and aesthetics. There are some Indian labels doing well internationally and I want to strategically position ASA to make sure it stands distinguished. This should also help me sustain my business in India.

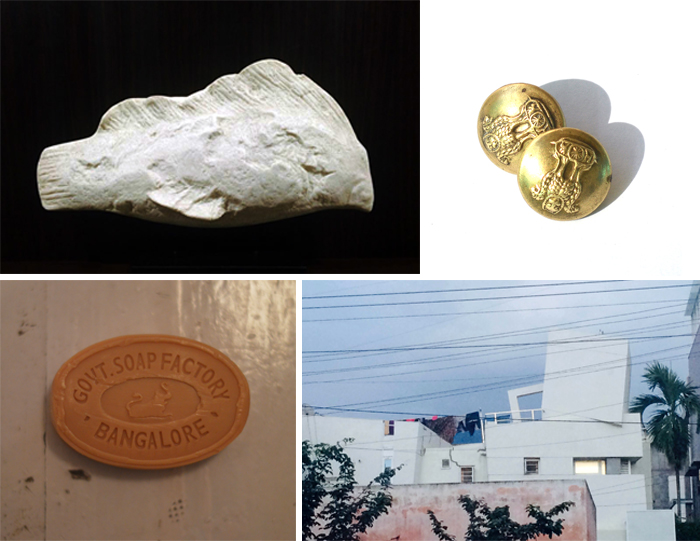

Above: images | Top: Beardfish sculpture at a hotel in Hyderabad; Brass buttons from chor bazaar in Mumbai | Below: Mysore Sandal Soap from Government Soap Factory in Bangalore; A house in Bangalore

Digital references > Masses Magazine The Acid e-flux Wearabout Dear

Work history >

ASA – Founder/Designer, Ahmedabad. January 2014 – present

Clay Club – Design Intern, Ahmedabad. 2013 – 2014

Amazing work